Engineering Pro Guides is your guide to passing the Mechanical & Electrical PE and FE Exams

Engineering Pro Guides provides mechanical and electrical PE and FE exam technical study guides, practice exams and much more. Contact Justin for more information.

Email: contact@engproguides.com

DESIGN

Chilled Water Pump Design Guide

Section 1.0: Introduction

The purpose of this guide is to provide the necessary background information on the Chilled Water Pump calculator to be able to use the calculator and to fill out a chilled water pump schedule. This guide covers the overall chilled water system, the calculator and the chilled water pump schedule. The overall chilled water system will help you to visualize how the chilled water pump fits within the overall system and will also help you to determine the hydraulically remote run for pressure drop calculations. Following the overall chilled water system, the inputs, outputs and references used in the calculator will be covered. The primary purpose of the calculator is to find the total dynamic head for use in the Chilled Water Pump Schedule. Lastly, each individual item within the Chilled Water Pump Schedule will be discussed in order to give you more knowledge on how to complete the schedule for your specific chilled water pump application.

The primary units that are used in the calculator are United States Customary System Units (USCS). As such, this guide focuses exclusively on the USCS. However, an SI version will also be provided in the future.

Section 1.1: Disclaimer

In no event will Engineering Pro Guides be liable for any incidental, indirect, consequential, punitive or special damages of any kind, or any other damages whatsoever, including, without limitation, those resulting from loss of profit, loss of contracts, loss of reputation, goodwill, data, information, income, anticipated savings or business relationships, whether or not Engineering Pro Guides has been advised of the possibility of such damage, arising out of or in connection with the use of this document/software or any referenced documents and/or websites.

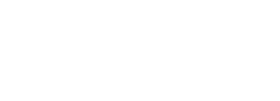

Section 2.0: Overall Chilled Water System

This guide covers the design and selection of a chilled water pump. The chilled water pump is a part of an overall chilled water system that often includes a chiller, piping, valves/fittings, expansion tank, air handling units and fan coil units. The chilled water pump is used to circulate chilled water in a closed system. The chilled water pump circulates return chilled water from the air handling units & fan coil units back to the chiller. The chiller then cools the chilled water and the chilled water is then supplied back to the air handling units and fan coil units.

The chilled water pump must be sized properly to circulate the correct amount of flow at the correct pressure in order to achieve proper cooling within the building. If there is insufficient flow and pressure, then there will not be enough cooling and the building may get hot during periods of high cooling load. If there is too much pressure and flow, then the electrical system will be unnecessarily burdened and if there is no speed control, then electricity may be wasted due to excess pumping.

Section 4.0: Selecting the Inputs

In order to best use the chilled water pump calculator you should have an understanding of the inputs and how changes in the inputs will affect the output.

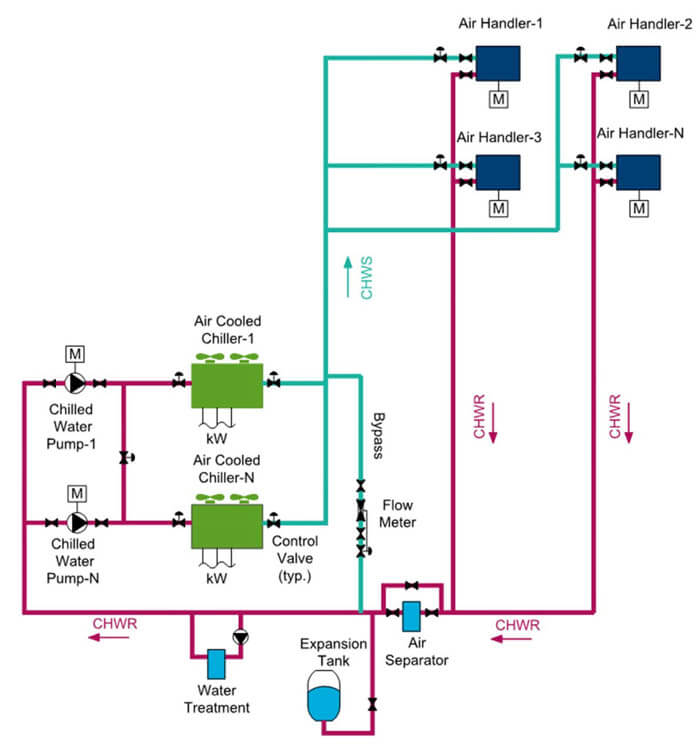

Section 4.1: Fluid Information

The fluid information required includes the fluid type, temperature, density and kinematic/dynamic viscosity.

Fluid Type: There are several fluid types of available for use in the calculator, including water, propylene glycol mixtures and ethylene glycol mixtures. If you select a fluid type from the drop down menu and a temperature, then the calculator will automatically fill in the properties for density, dynamic viscosity and kinematic viscosity. If your fluid type is not available in the drop down menu, then you must manually input all the values into the calculator, in order for the calculator to work.

Temperature: The temperature is used by the calculator to automatically find the density, dynamic viscosity and kinematic viscosity from the fluid properties built-in to the calculator. If you are not using one of the drop-down fluid types, then the temperature is not necessary to get an output from the calculator.

The typical chilled water temperatures are shown below. You should select the lowest supply chilled water temperature.

- • Supply Chilled Water: 42 F to 48 F/5.56 C to 7.78 C

- • Return Chilled Water: 52 F to 58 F/5.56 C to 7.78 C

Density: The density is used in the calculations to find the Reynolds Number. The Reynolds Number is used to find the friction loss coefficient.

Dynamic Viscosity: The dynamic viscosity is used in the calculator to find the Reynolds Number.

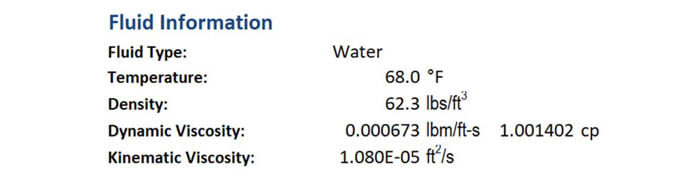

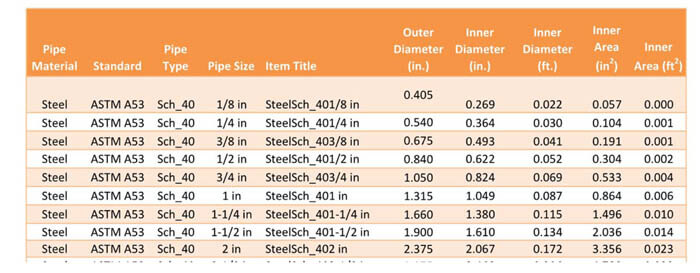

Pipe Information

The calculator requires you to insert the pipe section information which includes the flow rate, pipe material, pipe type, pipe size and length of pipe. A different pipe section should be used if any of these variables are changed.

There are various pipes available for use in the calculator but you can also add your own pipe information. The pipes built-in to the calculator include ASTM A53 Steel (Schedule 40 & 80), ASTM B88 Copper (Type K, L & M), ASTM D2241 PVC (SDR 26) and ASTM F2389 Polypropylene (DR 9). These are the most common pipes used in chilled water pipe application. If you have a special case, then please use the references sheet to add in your pipe information or contact Justin via email justin@engproguides.com.

Each pipe material and pipe type within that pipe material have its own standard pipe sizes. For example, Schedule 40 Steel does not have a 5/8 inch pipe size. When you change pipe materials and pipe types, please also change the pipe size to ensure the pipe size you want is available within the standard. The calculator will give you an error if you select a non-standard pipe size within the pipe material & type.

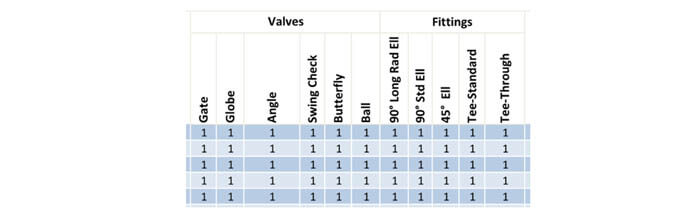

Valve and Fitting Information

The valves and fittings section requires you to put in the values for each fitting that are on a certain pipe section. A pipe section is defined as having the same flow rate and same pipe information.

The valve and fitting quantities are matched to 3-K values within the references tab. If you have a special valve and fitting, you can add in the 3-K values to the references tab. If you don’t have the 3-K values you can either choose a similar valve/fitting or you can estimate the pressure drop and add this to the equipment information section.

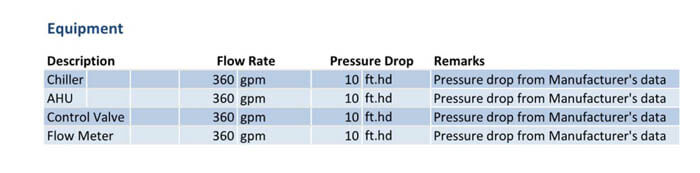

4.4 EQUIPMENT INFORMATION

The equipment section requires you to insert the flow rate and pressure drop for each piece of equipment. You should also indicate if the equipment is on the hydraulically remote run. Remember, only items listed as hydraulically remote will be used to calculate the pressure drop for the chilled water pump.

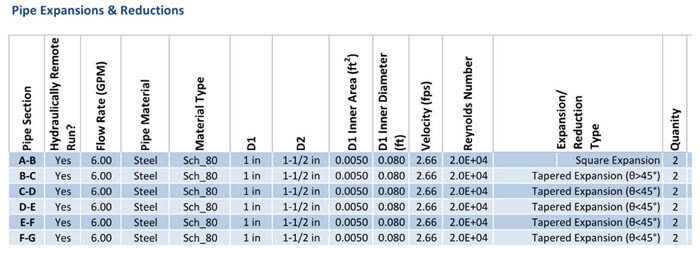

4.5 PIPE EXPANSIONS & REDUCTIONS INFORMATION

Pipe expansions and reductions use different equations to calculate pressure drops than those used for pressure loss through straight length of piping and through valves & fittings. Pipe expansion and reductions are dependent on the ratio between the two different pipe diameters. For example, the pressure drop through a 4”- 6” pipe expansion is less than the pressure drop through a 2” – 6” pipe expansion.

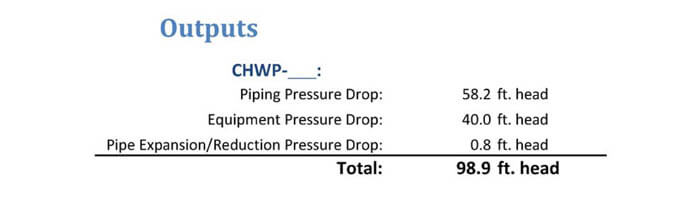

Section 5.0: Understanding the Outputs

This section covers the equations that use the inputs and references to create the outputs in the calculator.

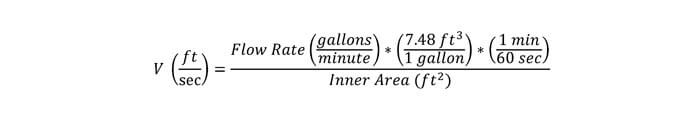

5.1 FLUID VELOCITY

The first equation uses the inputs from the pipe information section and the user input flow rate to find the fluid velocity in the pipe. When you choose the pipe material, pipe type and pipe size, the calculator will automatically determine the inner area from the table within the references. If the combination of pipe material, pipe type and pipe size is not in the calculator then a “N/A” will appear in the velocity column. You should double check to make sure the combination exists before proceeding.

5.2 REYNOLDS NUMBER

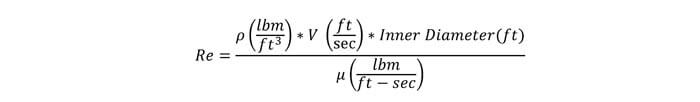

The first equation uses the inputs from the pipe information section and the user input flow rate to find the fluid velocity in the pipe. When you choose the pipe material, pipe type and pipe size, the calculator will automatically determine inner diameter and inner area and use this information to calculate the fluid velocity, along with the Reynolds Number.

The next equation calculates the Reynolds Number. This equation uses the velocity from the previous equation along with the pipe inner diameter and the fluid properties (density & viscosity).

The Reynolds Number classifies the fluid flow into either (1) Laminar, (2) Transition or (3) Turbulent. The breakdown between these three classifications is defined below. The friction calculations are most accurate with fluid flow in the turbulent region. For this reason, the calculator will highlight in red any Reynolds Number that is below the turbulent region.

Laminar→Re less than 2,000

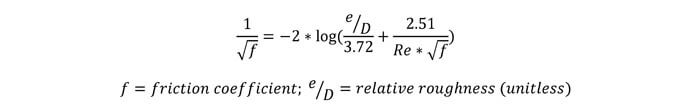

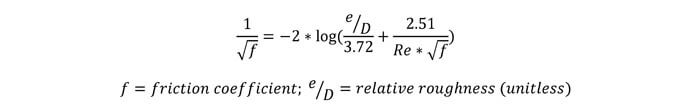

5.3 FRICTION FACTOR

The friction factor is found through the Colebrook Equation. The Colebrook Equation relates the friction factor to the Reynolds Number and the relative roughness.

Iterative Process: Since the friction coefficient is on both sides of the equation, you must use an iterative process to find the friction coefficient. You must first choose a value for the friction coefficient on the right side of the equation and then solve for the friction coefficient on the left side. Then use the friction coefficient that you just computed and plug-in this value to the right side of the equation and repeat the process. The process ends when the right and left side friction coefficients converge to nearly the same number. The calculator completes this process by running nine iterations.

Turbulent Flow: This equation only works for turbulent flow. A different equation is used for laminar flow. Luckily in practical chilled water applications, flow is nearly always turbulent. However, the calculator does incorporate conditional formatting to visually tell you if the flow is not turbulent. You should use your knowledge of the turbulent range from the previous section to ensure that your flow calculations are in the turbulent range.

5.4 PRESSURE DROP

The next step in the calculator is to calculate the pressure drop for the four different categories, (1) Piping, (2) Valves & Fittings, (3) Equipment and (4) Expansions/Reducers. Each of the four categories has their own specific equations, but (1) and (2) are included in the same line item on the calculator The next paragraphs will go through the calculations for each of the four categories.

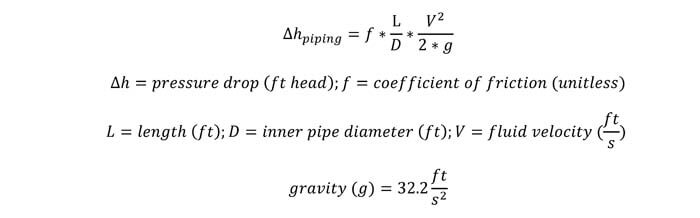

5.4.1 PRESSURE DROP – PIPING & VALVES/FITTINGS

The pressure drop for a straight length of piping is found through the friction factor and the Darcy Weisbach equation. This equation uses the velocity, friction factor, pipe inner diameter and the length of piping to calculate the pressure drop. For more details, see the equation below. The output for this equation is the pressure drop in units of feet head.

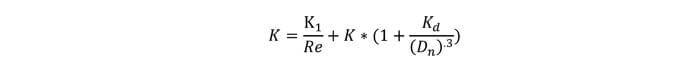

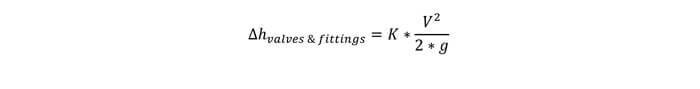

The pressure drop through valves and fittings is found through the 3-K method. The 3-K method uses three K-values to characterize each type of valve and fitting. These three K-values are K1, Kinf and Kd. These K-values are used with the Reynolds Number and nominal pipe diameter to find the final K-value.

Since, the calculated K-value is a function of Reynolds Number and nominal pipe diameter, the K-value is applicable for various pipe sizes, pipe materials, fluids and fluid velocities. Once you have the K-value, the K-value is used to calculate the pressure drop through the valves and fittings.

5.4.2 PRESSURE DROP – EQUIPMENT

There are no equations governing the pressure drop in equipment section. In this section of the calculator you can input the values for pressure drop at equipment. Typical equipment includes chillers, strainers, fan coils, flow meters, control valves and air handling unit coils. The pressure drop through this equipment at a specified flow rate must be provided by the manufacturer of the equipment. Typically, the manufacturer will provide a single value that indicates the pressure drop at a specified flow rate (GPM). This is typical of chillers, fan coils and air handling units. Other times, a manufacturer will provide a graph that shows the pressure drop at various flow rates. This is typical of flow meters, control valves and strainers.

5.4.3 PRESSURE DROP – EXPANSIONS/REDUCERS

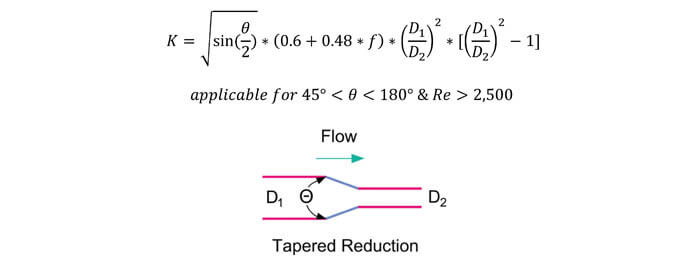

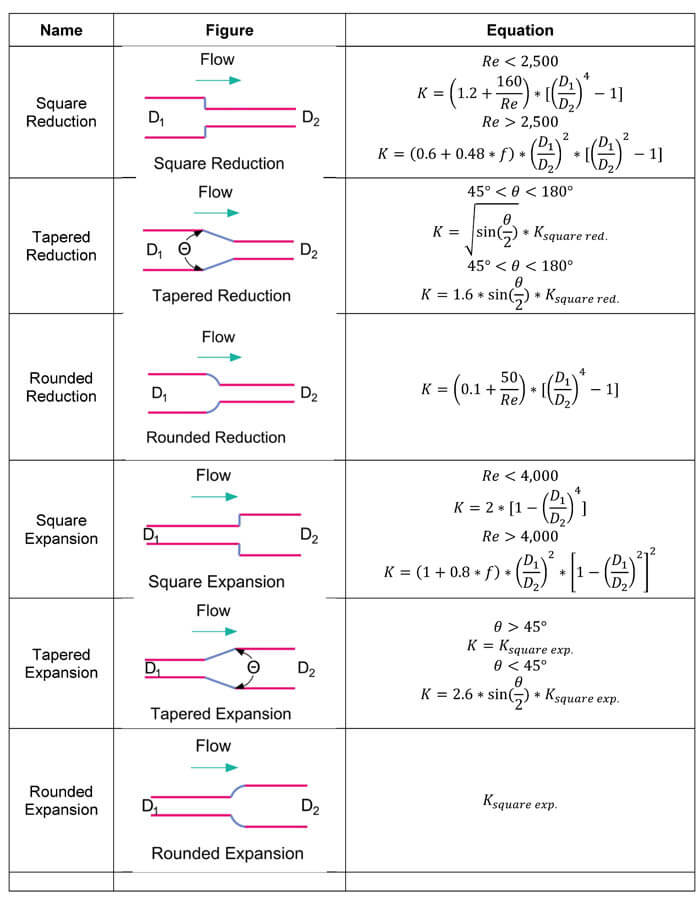

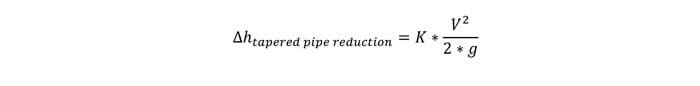

The last pressure drop calculation is the pressure drop due to pipe expansion and reductions. These pipe expansions and reductions occur when there is a change in pipe size. This calculation is dependent on the shape of the pipe size change. For example, the shape could be square, rounded, tapered and the pipe size change could be sharp or gradual. Each type of pipe size change has its own equation

An example of the equations used in the calculator includes the square reduction equation. First, you must solve for the K-value.

The calculator automatically ensures that you are meeting the requirements of the equation. There are other equations for each pipe expansion/reduction and each set of requirements as shown in the table below.

Once, the K-value is calculated, then the calculator calculates the pressure drop with the below equation.

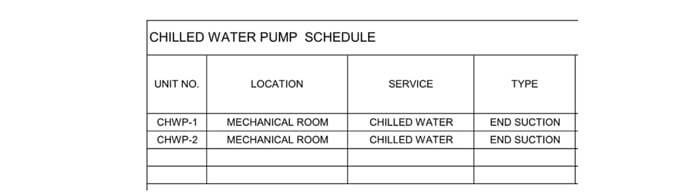

Section 6.0: Chilled Water Pump Schedule

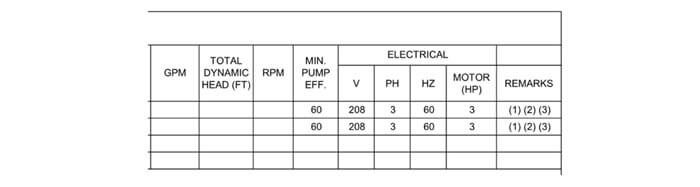

The design and selection of a chilled water pump typically results in the completion of the chilled water pump schedule. A sample schedule is provided in the calculator as a separate sheet. The chilled water pump schedule provides all the necessary design requirements to purchase the chilled water pump. This includes, pump type, flow rate, total dynamic head, pump speed, pump efficiency and motor information. There are a few other non-pump design requirements like the location and unit number and a section called remarks for pump design requirements that do not fit under the previously mentioned categories.

6.1 FLOW RATE (GPM)

The flow rate for the chilled water pump is typically determined by the maximum flow of the chiller or through the maximum flow rate required by the fan coils and air handling units.

6.2 TOTAL DYNAMIC HEAD (FEET HEAD)

The total dynamic head is found through the excel calculator. This total dynamic head is the total pressure drop in the most hydraulically remote run from the chilled water pump supply from the pump to the chilled water return of the pump.

6.3 SERVICE

This column is used to clarify the fluid of the pump, since these schedules may often be used as a general pump schedule. A general pump schedule could include chilled water pumps, condenser water pumps, hot water pumps, etc. In this case, the service column could be removed since the entire schedule is dedicated to chilled water pumps.

6.4 LOCATION

Chilled water pumps are typically located in a mechanical room with or near the chiller(s). The chilled water pump should be located with sufficient net positive suction head to ensure proper operation of the pump.

For more information on net positive suction head, please see the condenser water pump and expansion tank guides and calculators.

6.5 PUMP TYPES

There are three main types of pumps, centrifugal, rotary and reciprocating pumps. Rotary and reciprocating pumps are positive displacement pumps. This guide will not cover positive displacement and reciprocating pumps in detail because they are not typically used for chilled water pumps.

Centrifugal pumps are the most common type of pumps used for chilled water applications. The following information is tailored to centrifugal pumps and should not be applied freely to positive displacement pumps.

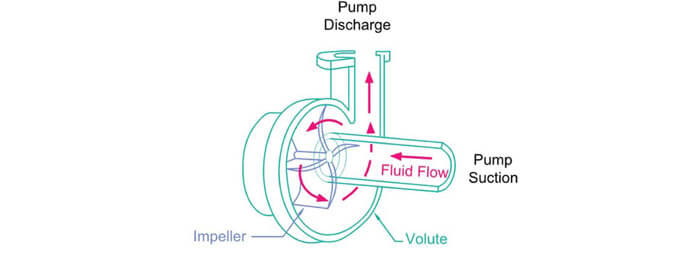

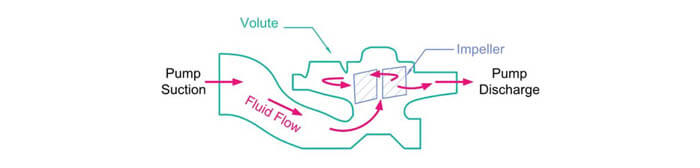

Centrifugal pumps operate on the principle of "centrifugal force", which is the conversion of rotational kinetic energy imparted by rotating impellers onto the liquid to produce a flow rate (kinetic energy) at a certain pressure (pressure energy). Fluid enters the pump at the center or eye of the impeller. The rotating impellers then push the fluid to the outer edges, imparting a flow rate and pressure.

There are two main types of centrifugal pumps, in-line and end-suction. These two types are discussed below.

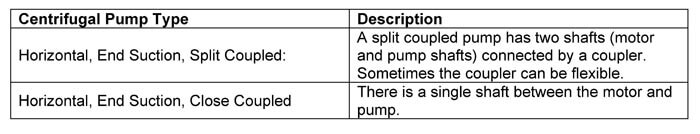

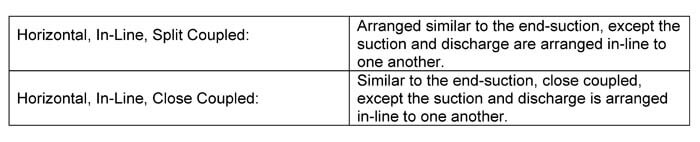

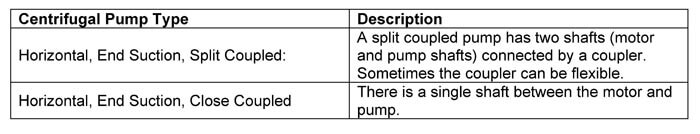

Within each centrifugal pump type (end suction & in-line) are horizontal and vertical type pumps, which are characterized by the orientation of the pump shaft as either horizontal or vertical. In addition, pumps can be further classified by the number of stages that the fluid proceeds through. Finally the last classification is how the pump is connected to the motor. Pumps can be long-coupled where the pump is connected to the motor by a flexible coupling or they can be close-coupled where the connection between the pump and motor is through a rigid coupling. The table below is a summary of the most common chilled water pump types.

The same four types of pumps also can be found with a vertical arrangement.

Another type of pump that is used for larger flow rates is the split case type. This centrifugal pump type has two chambers (split case) as opposed to the single chamber for end suction and in-line pumps.

6.6 PUMP EFFICIENCY

The typical pump efficiencies are within the range of 60% to 80%. You should select a pump that has its best efficiency point near your design operating point (typically around 10%). For example, if the best efficiency point of a pump is 72%, then you should choose this pump if your operating point is greater than 62% efficiency.

6.7 PUMP SPEED

The pump speeds available for chilled water pumps include 1,200, 1,800 and 3,600 RPM. When you choose the pump speed, you must first ensure that the pump manufacturer has that speed available. Lower pump speeds are preferred because the increased number of rotations will cause increased wear and tear. Bearings lifetimes are rated based on number of rotations, so if the rotations are reduced, then the bearings should have a longer life. This is true of all rotating objects. The most common pump speed is 1,760 RPM and then 3,500 RPM. The 1,160 RPM is sometimes used for smaller pumps with motors less than 5 HP.

Sometimes the pump manufacturer will indicate a speed slightly below 1,200, 1,800 or 3,600. This is because the motor is an induction motor as opposed to a synchronous motor. This means that electrically the rotation will be 1,200, 1,800 or 3,600 RPM, but the shaft will lag slightly behind this rotation.

6.8 MOTOR

The motor provides the necessary mechanical power to rotate the impeller within the pump. A motor takes in electrical power and converts the power to rotation. The motor must be able to meet the brake horsepower requirements of the pump. This is based on the pump flow rate, pump pressure and the efficiency of the pump.

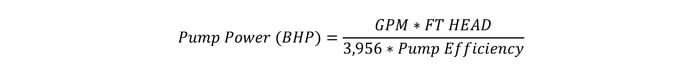

With these inputs, the brake horsepower of the chilled water pump is calculated with the following equation.

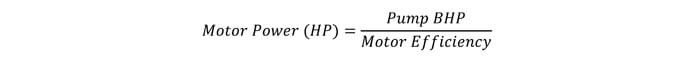

The pump needs a motor to provide the power to spin the pump. The motor will need to provide more than the pump power because there will be losses due to motor inefficiencies. Typically motor efficiencies range from 90% – 95%.

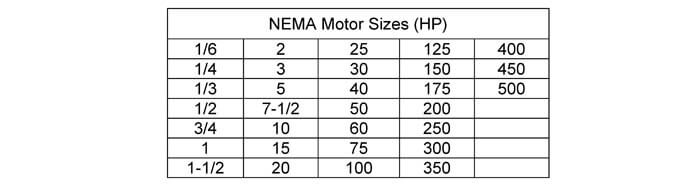

The calculated motor horsepower must be less than the available motor horsepower ratings. The available horsepower motor ratings are shown in the table below.

Pump manufacturers have online software that automatically shows the available pumps for a given flow rate and pressure drop. The software will show the speed (RPM), efficiency, brake-horsepower (BHP) and horsepower (HP) for the various pump types that can meet the required flow rate and pressure drop.

Sample Online Pump Selector: https://www.pacopumps.com/PumpSelect.aspx

Although the pump selection tool makes it very easy to select pumps, you should also know how to select pumps via the pump curves. A pump curve shows the pressure and flow rate operating points for a pump operating at various speeds or impeller diameters. If a pump speed is selected (1,200, 1,800 or 3,600) for a pump, then the pump curve graph will show multiple pump curves at various impeller diameters. If an impeller diameter is selected, then the pump curve graph will show multiple pump curves at various speeds. The following figure shows a specific pump speed, with multiple pump curves at various impeller diameters.

The graph also shows curves of pump horsepower in blue. These curves are created by calculating the horsepower based on the pressure, flow rate and pump/motor efficiency at a point. The efficiency curves shown on the figure are found based on a series of tests of the actual pump.

6.9 REMARKS, ADDITIONAL FEATURES

A chilled water pump will often require additional features besides the basic requirements that were discussed previously.

Non-Overloading Pump: A non-overloading pump is a pump with a sufficiently sized motor that can provide enough power at all operating points along a pump curve. For example, in the previous figure a non-overloading pump with 6” impeller diameter will have a 1-1/2 HP motor. At every point on the red curve, the horsepower required is less than the 1-1/2 blue HP curve.

Premium Efficiency Motor: A premium efficiency motor describes a motor that has a minimum efficiency specific to each motor horsepower in compliance with NEMA Premium Efficiency Motor Standards. The motor standards can be found in the below links. As an example, an energy efficient 5 HP/1,800 RPM motor will have an efficiency of 87.5% and a premium efficient motor will have an efficiency of 89.5%.

https://www.nema.org/Policy/Energy/Efficiency/Pages/NEMA-Premium-Motors.aspx

https://www.energy.gov/sites/prod/files/2014/04/f15/amo_motors_handbook_web.pdf

Variable Frequency Drive: A variable frequency drive is used to increase the speed of the pump rotation, which causes the pump curve to shift up and down. This causes the pump to provide more flow/pressure as the speed is increased and less flow/pressure as the speed is decreased.